Storing Energy Using Graphite

Posted by Big Gav in australia, cloncurry, energy storage, flow battery, graphite, king island, lloyd energy systems, vanadium

The Canberra Times recently published an article, rather misleadingly entitled "Generating solar energy in the dark", which looked at the use of purified graphite for thermal energy storage.

The company developing the technology is called Lloyd Energy Systems, which is prototyping solar energy storage, a wind-to-heat plant and a small-scale plant that combines water treatment, energy storage and steam turbine generation.

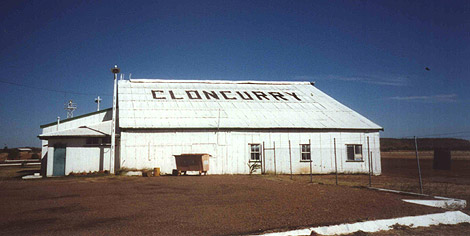

The company has received a $5 million Federal Government grant as part of its advanced energy storage technology program in the western NSW town of Lake Cargelligo, with Country Energy agreeing to purchase the power generated. Lloyd Energy also has an agreement with Ergon Energy in Queensland to build a $30million plant at Cloncurry in Queensland, partially funded by the Queensland state government, which the Sydney Morning Herald reported on last year.

[Lloyd Energy CEO] Mr Hollis said large amounts of coal-fired energy were lost during long transmission to remote areas. As power loads built up over time, mainly because of demand for air-conditioners, the grid could no longer cope in peak periods. Towns at the end of the line suffered the most from power shortages.

"We're putting environmentally friendly generation out at the end of the branches of the tree if you like, so it can pump energy back in when the branches are in trouble," he said. "It actually serves three purposes. Firstly, it is a renewable energy replacement for coal. Secondly, it avoids the country energy authorities having to upgrade their transmission lines so they can get more power out in the peak." The third benefit was having an energy source at the end of the line that could return power into the grid.

Sixteen full-scale models would go to Lake Cargelligo and 54 to Cloncurry. The system's mobility and flexibility had caught the attention of key Australian mining companies, which use diesel and gas generators.

Mr Hollis said making renewable energy available when it was required added to the system's value. ... "You can store thermal energy in a lot of things, but high-purity graphite is an extremely efficient way of storing it it doesn't have any losses. You can move the heat in and out very quickly."

Graphite based storage does not seem to have been used anywhere else in the world thus far. Storage for renewable energy has usually been limited to compressing air underground (Compress Air Energy Storage or CAES), where it can later be released under pressure, or pumped hydro, where the power is used to pump water back up into dams that can generate hydro-electricity. While both techniques are effective, they require suitable locations and complex infrastructure to be put in place.

The Queensland project will make Cloncurry the first town in Australia to rely exclusively on solar power, produced by a concentrated solar power (CSP) system. The system contains almost 7200 mirrors, which will guide the sun's rays into holes in the bottoms of 54 elevated graphite cubes, heating them to 1800 degrees (C). The stored heat is then used to generate steam for turbines on demand. The company claims the turbine will use less water than falls in an average year on the power station's roof.

Wind to Heat on King Island

A third system using the graphite system is being planned by CBD Energy, which has licensed the Lloyd technology and will build a wind-powered version of the system on King Island. The island, in the Bass Strait north-west of Tasmania, currently relies primarily on diesel to generate power for its 1800 residents.

The joint venture with Hydro Tasmania is not expected to make the island wholly powered by renewable energy, but it will eliminate the need for 1.25 megalitres of diesel fuel a year, says CBD's chief engineer, John Giannasca.

CBD plans to install two megawatts of wind turbines to supplement existing systems along with six graphite blocks. The blocks are each the size of a standard shipping container, and will be heated to 800 degrees (C).

Some solar panels will be also be installed for periods when the island is without wind, and there are ongoing investigations into harnessing ocean current and tidal energy in the region.

CBD Energy is run by ex-Impulse Airlines chief Gerry McGowan, with the company partly owned by German clean energy company Solon. CBD is also looking to develop solar energy projects in Australia, with plans for the first operation to be set up in the northern NSW town of Moree.

Graphite energy storage in context

King Island received a lot of press attention for an earlier project to store energy using Vanadium Redox flow batteries that began in 2003.

The company involved in that initiative, Pinnacle VRB, has since changed name to Cougar Energy and doesn't seem to have any active VRB projects going.

Another Australian company developing a slightly different form of Vanadium based batteries (Vanadium Bromide) is VFuel, though there hasn't been much news from them in some time either. Both VFuel and Pinnacle/Cougar are using technology pioneered at the University of NSW.

What will happen to the flow battery installation isn't clear, though a visiting parliamentarian (pdf) reported in 2004 that "The vanadium batteries would appear to best suit the ironing out of the wind fluctuations rather than holding larger quantities of power. The battery is expensive and takes up considerable space" and that graphite was being considered as an alternative.

TreeHugger noted last year that the advantage the Lloyd Energy graphite system has is that they have apparently managed to figure out how to refine low grade graphite into high quality crystalline graphite, and the storage capacity “ranges from around 300kWh (thermal) per tonne at a storage temperature of 750°C to around 1000kWh (thermal) per tonne at 1800°C.”.

The Australian Greenhouse Office has a review paper on Energy Storage Technologies (pdf), published in 2005, which includes a brief look at graphite in a section on thermal energy storage.

Thermal energy storage systems use material that can be kept at high temperatures in insulated containments. Heat recovered can then be applied for electricity generation using steam Rankine cycle or other heat engine cycles. Energy input can, in principle, be provided by electrical resistance heating but the overall round trip efficiency will be low. However, as with thermochemical energy storage, thermal systems have considerable advantages when integrated with Concentrating Solar Power (CSP) technologies (ie parabolic troughs or dishes, central receiver/heliostat systems and Linear Fresnel systems).

Integration of thermal storage for several full load hours, together with new storage materials and advanced charging/discharging concepts, would allow for increased solar thermal electricity production without changing the power block size (ECOSTAR, Nov 2004). Provided that the storage is sufficiently inexpensive, this would lower the levelised energy cost, and additionally increase the dispatchability of the electricity generation.

The kind of storage system used for solar energy storage depends on the Concentrating Solar Power (CSP) technology, the heat transfer medium used and the required temperature of operation. In general, high-temperature thermal storage development will need several scale-up steps over an extended development time before market acceptance will be achieved.

Storage systems for thermal energy storage need to:

• be efficient in terms of energy loss and temperature drops

• have low cost

• have a long service life

• have low parasitic power requirements.

The development of storage systems for high pressure steam and pressurized, high temperature air, is especially challenging. If or when developed, such storage systems would lead to a significant drop in CSP electricity costs. The high-temperature thermal storage technologies utilised or under development now are (ECOSTAR, Nov 2004):

Molten salt storage and Room Temperature Ionic Liquids (RTILs)

• State of the art is the 2-tank molten salt storage tested in the “Solar Two” Central Receiver Solar Power Plant demonstration project in California, combined with using molten salt as heat transfer fluid. The use of new, so called Room Temperature Ionic Liquids (RTILs) has recently been proposed. RTILs are organic salts with negligible vapour pressure in the relevant temperature range and a melting temperature below 25°C. Room temperature ionic liquids are new materials that have the potential to be stored at temperatures of many 100s of degrees without decomposing. It is not yet clear whether they are stable up to the temperature level required for CSP and also whether they may be produced at reasonable costs.

Concrete Storage

• The concept of using concrete or castable ceramics to store energy at high temperatures for parabolic trough power plants with synthetic oil as the heat transfer fluid (HTF) has been investigated in European projects. The implementation of a concrete storage system is claimed (ECOSTAR, Nov 2004) to be able to be realised within less than 5 years.

Phase Change Materials (PCM)

• Phase change materials are materials selected to have a phase change (usually solid to liquid) at a temperature matching the thermal input source. The high “latent heat” in a phase change offers the potential for higher energy storage densities than storage of non phase change high temperature materials. Because a solid/liquid phase change is involved, a heat transfer fluid is needed to move heat from source to PCM. At present, two principle approaches are being investigated:

- encapsulation of small amounts of PCM

- embedding of PCM in a matrix made of another solid material with high heat conduction.

• The first measure is based on the reduction of distances inside the PCM and the second one uses the enhancement of heat conduction by other materials (e.g. graphite). Storages based on PCM are in an early stage of development but the cost target is to stay below A$34/kWh based on the thermal capacity. Although the uncertainties and risks of the PCM storage technology are in a medium range, the technology time required for full development and commercial implementation is likely to be more than 10 years (ECOSTAR, Nov 2004).

Storage for air receivers using solid materials

• Storage types using solid material for sensible heat are normally used together with volumetric atmospheric or pressurized air systems. The heat has to be transferred to another medium, which may be any kind of solid with high density and heat capacity. Another innovation is to develop for pressurised closed-air receivers a storage container that has to be pressure resistant up to about 16-20 bar depending on the gas turbine pressure ratio.

• For both cases the time for development and implementation is considered to be between 5 to 10 years and the risks and uncertainties are in the medium range (ECOSTAR, Nov 2004).

Storage for saturated water/steam

• The steam drum, which is a common part in many steam generators, is often used to provide process heat storage in industry. The main problem is the size of the steam vessel for larger storage capacity and the degradation of steam quality during discharging. However, this storage type is ideal as buffer storage for short time periods of several minutes, to compensate shading of the solar field by fast moving small clouds. Using appropriate encapsulated PCM inside the storage could enhance the storage capacity because the latent heat content can be used to slow down the temperature and pressure decrease and enable smaller storage vessels for the same thermal capacity.

• Recently, underground thermal energy storage has been proposed again as a lowcost solution to high-temperature, low-loss thermal storage for CSP systems (Mills et al, Nov 2004). It involves storage of water under pressure in deep metal lined caverns where the pressure is contained by the surrounding rock and the overburden weight.

High-purity graphite.

• This readily available material has the attractive property of increasing its heat storage capacity as the temperature of storage rises. However, the relatively low temperatures of solar thermal systems are not optimal for this storage medium unless the graphite storage blocks could be positioned at the very high temperature focus of a concentrating solar collector.

For another good description of a range of energy storage technologies, try Richard Baxter's book "Energy Storage: A Nontechnical Guide".

One obvious advantage for graphite is that carbon is extremely common, unlike some of the minerals used in various battery technologies and so there will be no meaningful material "limits" to the creation of these. Perhaps one day we'll see CO2 being sequestered in the form of graphite blocks, ready to be installed into CSP power stations.

On semi-related news, energy storage has also been getting some attention in The Economist lately, courtesy of EEStor's ultracapacitor technology.